For years, our factory has maintained a consistent track record of supplying precision sheet metal parts to outstanding enterprises in the air – conditioning and refrigeration industry, with Gree Electric being a prominent example. This long – standing cooperation has not only made us an inseparable part of their supply chains but also deepened our understanding of the unique demands that the air – conditioning and refrigeration industry places on sheet metal parts.

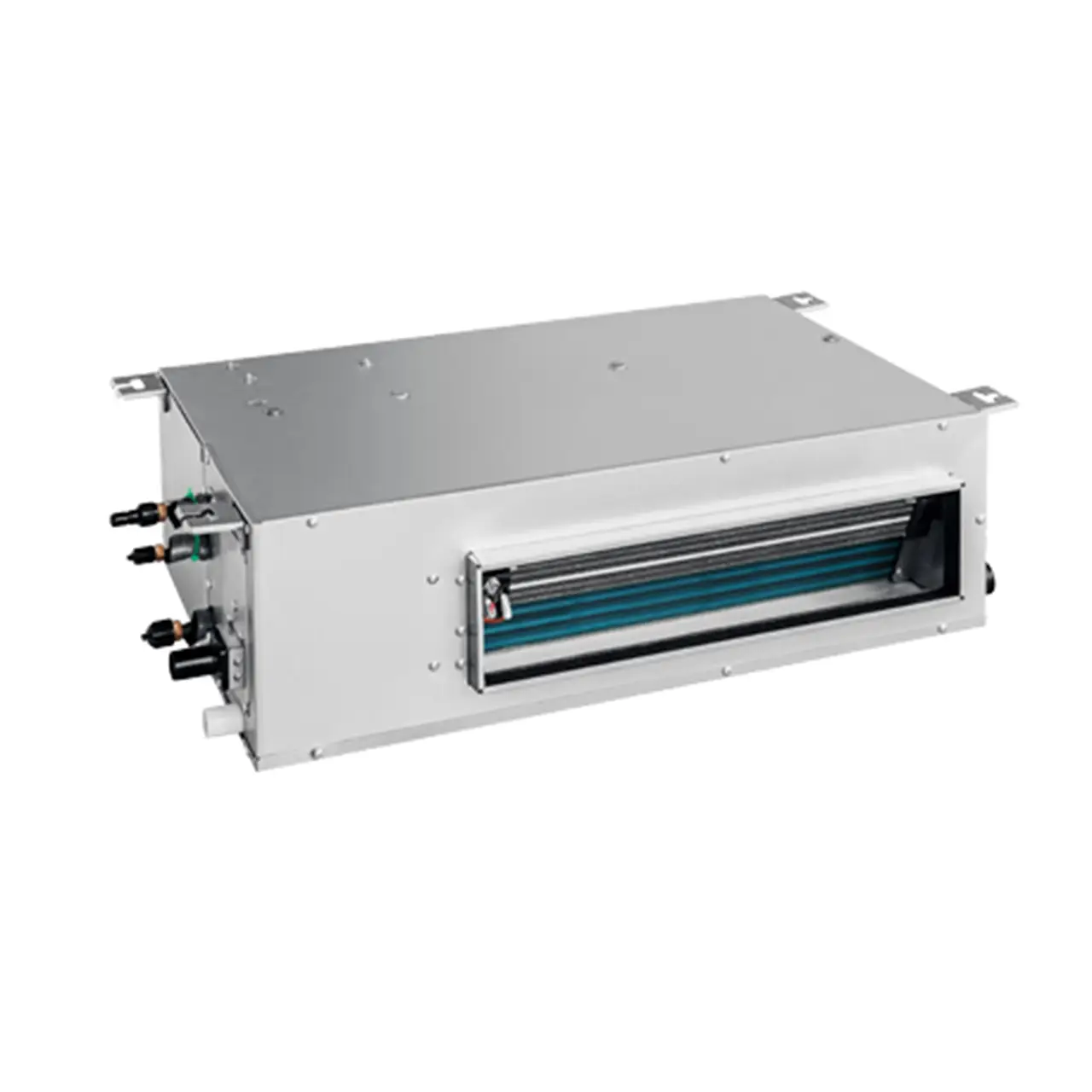

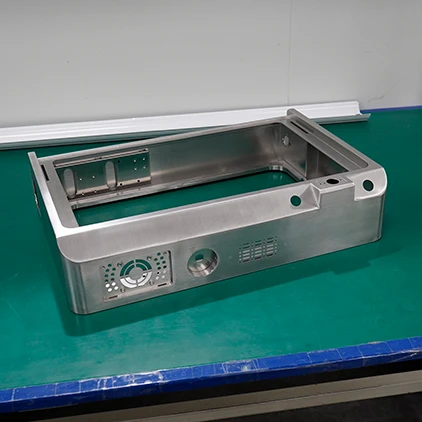

The air – conditioning and refrigeration industry has extremely strict requirements for sheet metal parts, and precision is the top priority. In air – conditioning systems, even a tiny error in the size of sheet metal parts can affect the overall performance. For instance, the sheet metal components that form the air ducts must have precise dimensions to ensure smooth air flow. If there is a deviation, it will lead to air leakage, reducing the cooling efficiency of the air – conditioner. Our factory, equipped with advanced manufacturing equipment and strict quality control systems, ensures that each sheet metal part meets the highest precision standards. We use high – precision laser cutting and CNC bending machines, which can control the error within a very small range, perfectly meeting the precision requirements of Gree Electric and other excellent enterprises.

Durability is another key demand of the industry for sheet metal parts. Air – conditioning and refrigeration equipment often work in harsh environments. Some air – conditioners are installed outdoors, exposed to wind, rain, and extreme temperatures. Refrigeration equipment, on the other hand, operates in low – temperature environments for a long time. This requires sheet metal parts to have strong corrosion resistance and temperature resistance. We select high – quality materials such as galvanized steel and stainless steel for production. These materials have excellent anti – corrosion properties, which can effectively resist the erosion of rainwater and humidity. At the same time, they can also maintain their structural stability in extreme temperature changes, ensuring the long – term and stable operation of the equipment.

Thermal conductivity is also an important factor that cannot be ignored. In refrigeration systems, sheet metal parts are in contact with refrigerants, and their thermal conductivity directly affects the heat exchange efficiency of the system. We have conducted in – depth research on the thermal properties of different materials and can choose the most suitable materials according to the specific needs of the equipment. For example, in the evaporator and condenser of refrigeration equipment, we use materials with good thermal conductivity to improve the heat exchange effect, thereby enhancing the refrigeration efficiency of the equipment. This is crucial for Gree Electric, which has always been committed to improving the energy efficiency of its products.

In addition to the above performance requirements, the air – conditioning and refrigeration industry also pays great attention to the cost – effectiveness of sheet metal parts. As a leading enterprise in the industry, Gree Electric has strict control over the cost of its products while pursuing high quality. Our factory has optimized the production process to reduce production costs on the premise of ensuring quality. We adopt large – scale production, which can reduce the unit cost of the products. At the same time, we have established a perfect supply chain management system to minimize the procurement cost of raw materials. This enables us to provide Gree Electric with high – quality and cost – effective sheet metal parts, helping them maintain their competitive advantage in the market.

Our long – term cooperation with Gree Electric and other excellent enterprises is based on our ability to meet these special needs of the industry. We have a professional technical team that can communicate closely with customers to understand their specific requirements for sheet metal parts. Then, we customize the production plan according to these requirements to ensure that the products meet the actual needs of the equipment. In the process of production, we implement strict quality inspection, and each sheet metal part must pass multiple inspections before leaving the factory. This ensures the stability and reliability of the products, which is why we can become an inseparable part of their supply chains.

Looking forward to the future, with the continuous development of the air – conditioning and refrigeration industry, the requirements for sheet metal parts will become more and more stringent. Our factory will continue to increase investment in research and development, improve the level of manufacturing technology, and strive to provide customers with better products and services. We believe that through our unremitting efforts, we will maintain a good cooperative relationship with Gree Electric and other excellent enterprises, and make greater contributions to the development of the air – conditioning and refrigeration industry.