Double-Layer Conveyor Systems: Optimizing Fruit Packaging for Australian Distributors

For Australian fruit distributors, efficiency and freshness are the cornerstones of successful operations. Our manufacturing facility has partnered with leading distributors to design and produce specialized double-layer conveyor systems that seamlessly transport packaging materials from the second floor to ground-floor fruit sorting lines. Tailored to handle two distinct package sizes while withstanding high-humidity environments, these systems have become integral to maintaining the integrity of fresh produce throughout the packaging process.

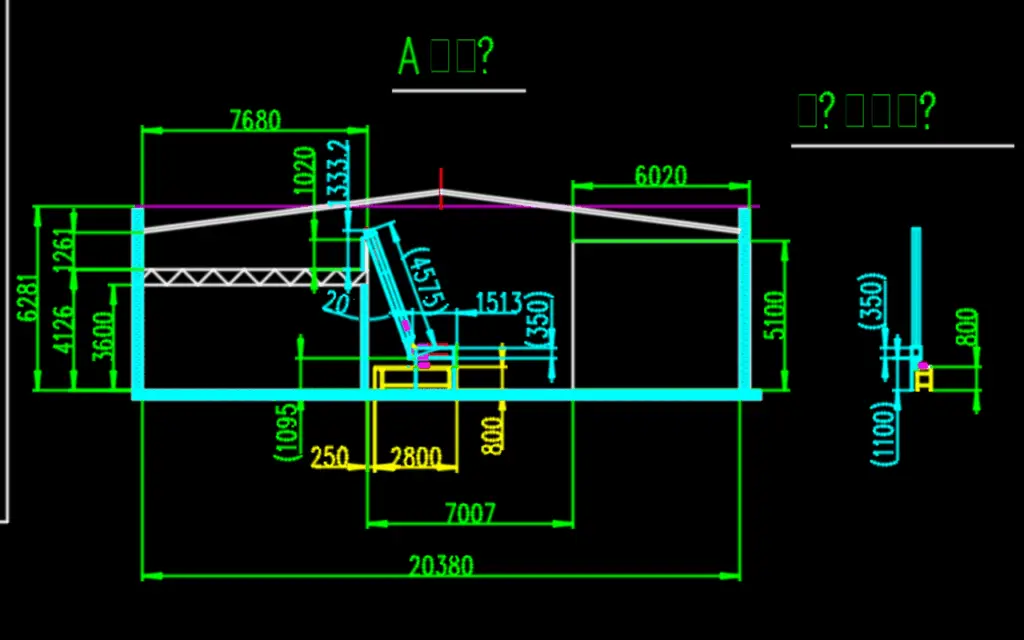

The dual-layer design of the conveyor system addresses a critical logistical challenge: streamlining the flow of diverse packaging materials in a busy facility. Australian fruit distributors often handle multiple product lines, from small berries to large citrus fruits, each requiring specific packaging sizes. The upper layer of the conveyor is engineered to transport larger crates and cartons, while the lower layer efficiently moves smaller pouches and wrapping materials. This separation eliminates bottlenecks, ensuring that packaging supplies reach sorting stations exactly when needed. Our engineering team optimized the incline angle and belt speed of each layer to match the weight and dimensions of the materials, preventing jams and minimizing friction-related wear—a crucial detail in high-volume operations where downtime can lead to significant losses.

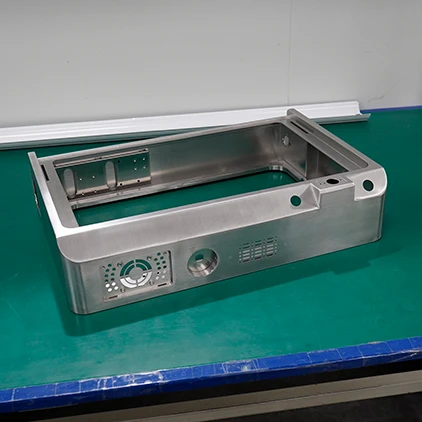

High humidity is inherent in fruit packaging facilities, as maintaining moisture levels between 85-90% is essential for preserving the freshness of produce like strawberries, grapes, and stone fruits. However, this environment poses unique challenges for metal components, as prolonged exposure to moisture can cause corrosion and structural degradation. To combat this, we construct the conveyor frames and components using marine-grade 316 stainless steel, a material renowned for its resistance to corrosion in humid and even coastal environments. Unlike standard 304 stainless steel, 316 contains molybdenum, which creates a protective oxide layer that withstands constant moisture and occasional contact with fruit juices or cleaning agents.

Equally critical is the welding (welding technique) used in assembling the conveyor systems. Traditional welding methods can leave micro-gaps where moisture accumulates, leading to hidden corrosion. Our solution employs TIG (Tungsten Inert Gas) welding, which produces clean, precise joints with minimal spatter. This process not only ensures structural integrity but also creates smooth, non-porous surfaces that resist water retention. All welds are further treated with a passivation process, removing any iron particles that could initiate corrosion and enhancing the steel’s natural protective properties. These measures guarantee that the conveyor systems remain durable even in the humid conditions of Australian fruit packing sheds.

Beyond material and design, the conveyor systems are integrated with features that enhance operational efficiency. Each layer is equipped with sensors that monitor material flow, alerting operators to potential blockages or low stock levels. The belts themselves are made from food-grade polyurethane, which is both moisture-resistant and easy to clean—an important feature for maintaining hygiene standards. Additionally, the systems are designed with modular components, allowing for easy maintenance and adjustments as distributors scale their operations or introduce new packaging formats.

Our collaboration with Australian fruit distributors has deepened our understanding of their unique needs, from compliance with strict food safety regulations to adapting to seasonal fluctuations in production volume. By combining corrosion-resistant materials, precision engineering, and practical design, we’ve created conveyor systems that not only streamline packaging workflows but also contribute to preserving the quality of fresh fruit from sorting to shipment. As the industry continues to evolve, we remain committed to innovating solutions that meet the demands of efficiency, durability, and food safety—ensuring that Australian-grown fruits reach markets in optimal condition.