For years, our manufacturing facility has been a trusted provider of high-quality enclosures for medical testing equipment, serving some of the most reputable enterprises in the industry. These partnerships have not only integrated us into their core supply chains but also deepened our expertise in addressing the unique demands that medical testing equipment enclosures must meet. As the backbone of protective and functional design for diagnostic tools, these enclosures play a pivotal role in ensuring accuracy, safety, and reliability in life-critical testing processes.

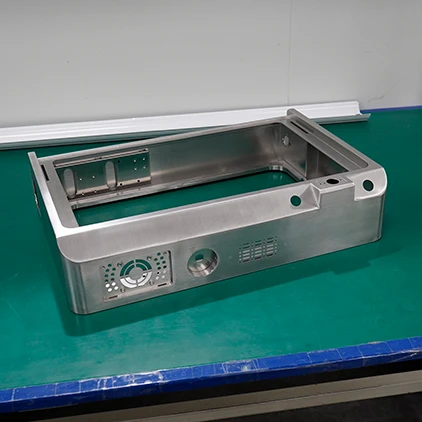

Precision in dimensional design is paramount for medical testing equipment enclosures. Unlike standard industrial casings, these enclosures must accommodate a complex array of internal components—from sensitive sensors to intricate circuit boards—with minimal tolerance for error. A misalignment of just a few millimeters can disrupt the calibration of equipment like PCR machines or hematology analyzers, leading to inconsistent test results. Our production process leverages advanced CNC machining and laser cutting technologies to achieve dimensional accuracy within ±0.1mm, ensuring that every enclosure fits seamlessly with internal parts. This precision is particularly critical for equipment used in molecular diagnostics, where even slight vibrations or misalignments can compromise the integrity of delicate reactions.

Material selection for these enclosures is guided by strict safety and durability standards. Medical testing environments often involve exposure to harsh chemicals, disinfectants, and frequent cleaning protocols. Enclosures must resist corrosion, withstand repeated sanitization, and maintain structural integrity over extended periods. We prioritize materials such as 316 stainless steel and medical-grade ABS plastic, chosen for their chemical resistance and biocompatibility. 316 stainless steel, for instance, offers superior protection against corrosive agents like ethanol and bleach, making it ideal for enclosures in laboratories handling infectious samples. Meanwhile, medical-grade ABS provides a lightweight yet robust alternative for portable testing devices, ensuring both durability and ease of handling.

Electromagnetic compatibility (EMC) is another non-negotiable requirement for medical testing equipment enclosures. Modern diagnostic tools rely on sensitive electronic components that can be disrupted by external electromagnetic interference (EMI) from other devices or power sources. Our enclosures are engineered with specialized shielding layers, often incorporating conductive coatings or metal alloys, to block EMI and prevent signal degradation. This is especially critical for equipment like MRI-compatible testing devices or fluorescence spectrometers, where electromagnetic stability directly impacts data accuracy. Through rigorous EMC testing, we ensure that our enclosures meet international standards such as IEC 60601, safeguarding the reliability of diagnostic outputs.

Hygiene and ease of cleaning are integral to the design of medical testing equipment enclosures. In clinical settings, where infection control is paramount, enclosures must minimize crevices and sharp edges that could trap contaminants. Our design team collaborates closely with clients to create smooth, rounded surfaces and sealed joints, eliminating potential harborage points for bacteria or viruses. Additionally, many of our enclosures feature tool-less access panels, allowing for quick and thorough cleaning without compromising the equipment’s internal components. This design philosophy aligns with the stringent hygiene protocols of hospitals and laboratories, reducing the risk of cross-contamination during testing procedures.

Customization is key to meeting the diverse needs of medical testing equipment manufacturers. From benchtop analyzers to large-scale automated testing systems, each device requires an enclosure tailored to its specific form factor and functional requirements. Our engineering team works alongside clients to develop bespoke solutions, incorporating features such as integrated cable management systems, ergonomic handles, and viewing windows made from shatterproof, chemical-resistant glass. For example, enclosures for blood gas analyzers often include specialized ports for sample insertion, designed to minimize exposure to ambient air and maintain sample integrity. This level of customization ensures that our enclosures not only protect internal components but also enhance the usability and efficiency of the equipment.

Our long-standing partnerships with leading medical testing enterprises are built on a commitment to meeting these rigorous standards. By investing in research and development, we stay ahead of emerging trends, such as the growing demand for compact, portable testing devices and the integration of AI-driven diagnostics. This proactive approach allows us to adapt our manufacturing processes—whether through adopting additive manufacturing for complex geometries or developing new material composites—to address evolving industry needs.

Looking forward, as medical testing technology continues to advance, the role of high-performance enclosures will only grow in importance. We remain dedicated to refining our designs, materials, and manufacturing techniques to ensure that our enclosures continue to support the industry’s mission of delivering accurate, reliable, and safe diagnostic tools. By maintaining our focus on precision, safety, and innovation, we are proud to remain an indispensable partner in the supply chains of the world’s leading medical testing enterprises.