Surface Treatment

Powder Caoting

Powder coating is a dry finishing process where finely ground pigment and resin particles are electrostatically charged and sprayed onto a surface. The coated item is then baked, melting the powder into a smooth, durable film.

This method offers superior adhesion, corrosion resistance, and color retention compared to liquid paints. It’s eco-friendly, producing minimal volatile organic compounds (VOCs). Widely used in automotive, architecture, and furniture industries, it accommodates various substrates like metal, MDF, and glass, with a vast range of finishes from matte to high-gloss.

Aluminum anodizing

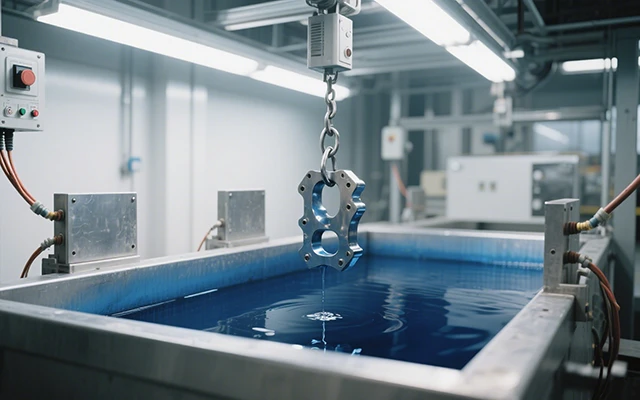

Aluminum anodizing is an electrolytic process that forms a protective oxide layer on aluminum surfaces, enhancing corrosion resistance, wear durability, and paint adhesion.

The process involves immersing aluminum (anode) in an electrolyte (usually sulfuric acid) and passing an electric current, which oxidizes the metal to create a porous, uniform film. This layer can be dyed in various colors or sealed for added protection.

Widely used in aerospace, automotive, and consumer g

Electroplating

Electroplating is a surface treatment process that deposits a thin layer of metal onto a substrate using electrolysis. It enhances corrosion resistance, improves aesthetics, and adds functional properties like conductivity or hardness.

The process involves immersing the workpiece (cathode) and a metal source (anode) in an electrolyte solution. An electric current drives metal ions from the anode to the cathode, forming a uniform coating. Common metals used include nickel, chrome, gold, and zinc, applied in industries from automotive to electronics.

Sandblasting

Sandblasting is a surface treatment process that uses high-pressure air to propel abrasive materials (such as sand, glass beads, or aluminum oxide) against a workpiece. This technique cleans surfaces by removing rust, paint, or contaminants, and can also texture materials for improved adhesion of coatings or enhanced aesthetics.

Widely used in automotive, aerospace, and manufacturing industries, it adjusts surface roughness to meet specific functional or decorative requirements. The intensity and abrasive type are tailored to the material—from metal and wood to concrete—ensuring precise results without damaging the substrate.